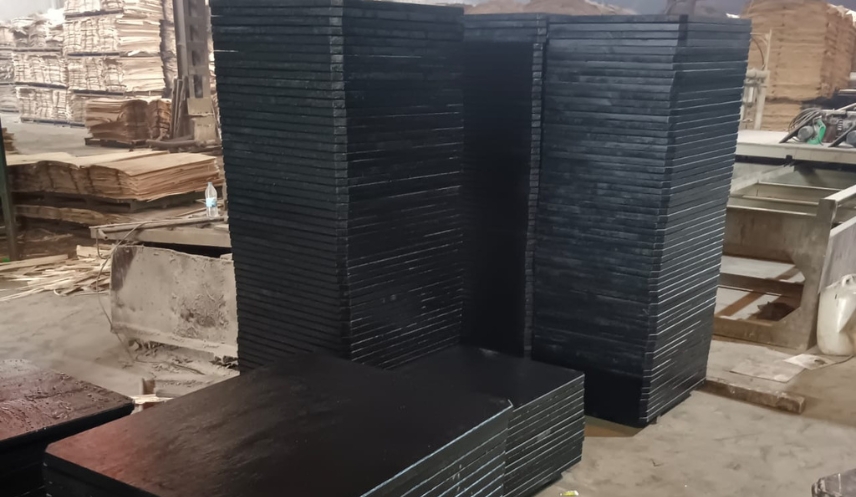

PWS Pallets are expertly crafted using carefully selected hardwood veneer and high polymerized resol type thermosetting plastic resin. This results in a high-density product with a thermoset added black plastic overlay of 270 GSM, providing exceptional abrasion resistance.

Our pallets are ideal for use with AAC blocks, concrete blocks, chemical treatment blocks, soil bricks, concrete bricks, pavers, tiles, ceramic tiles.

Available in a variety of formats, including thicknesses ranging from 25 to 75 mm, lengths from 305 to 1525 mm, widths from 305 to 1525 mm, and densities from 0.95 to 1.15 gm/cm3, our PWS Pallets offer versatility and durability for a wide range of applications

TECHNICAL SPECIFICATIONS

| Dimension | BIS Requirement | Observation Values |

|---|---|---|

| Length | + 3 / - 0 | 1526mm |

| Width | + 3 / - 0 | 1526mm |

| Thickness | 26mm | 25.50mm |

| Squareness | 2 mm/1000 mm | 0.95mm |

| Edge Straightness | 2 mm/1000 mm | 0.50mm |

| Workmanship & Finish | Clause 7 | Satisfactory |

Physical Properties

| Physical Property | BIS Requirement | Observation Values |

|---|---|---|

| Density | 0.95 gm/cm3 | 1.1 gm/cm3 |

| Moisture Content | 5-15% | 7.25% |

| Bond Quality Test |

a) No visible delamination in glue line and polywood face b) No forcible separation; fibre should be adhered between plies |

Satisfactory |

Strength Properties

| Property | BIS Requirement | Observation Values |

|---|---|---|

| Breaking Strength |

Along: 550kgf Across: 400kgf |

Along: 740kgf Across: 515kgf |

| Static Bending Strength (M.O.E. & M.O.R.) |

Along M.O.E.: Avg. 7500 N/mm2, Ind. 6700 N/mm2 Across M.O.E.: Avg. 4000 N/mm2, Ind. 3600 N/mm2 Along M.O.R.: Avg. 50, Ind. 45 Across M.O.R.: Avg. 30, Ind. 27 |

Along M.O.E.: 8650 N/mm2 Across M.O.E.: 5835 N/mm2 Along M.O.R.: 72 N/mm2 Across M.O.R.: 45.20 N/mm2 |

| Tensile Strength |

Along: 55 MPa Across: 50 MPa |

Along: 68.90 MPa Across: 58.22 MPa |