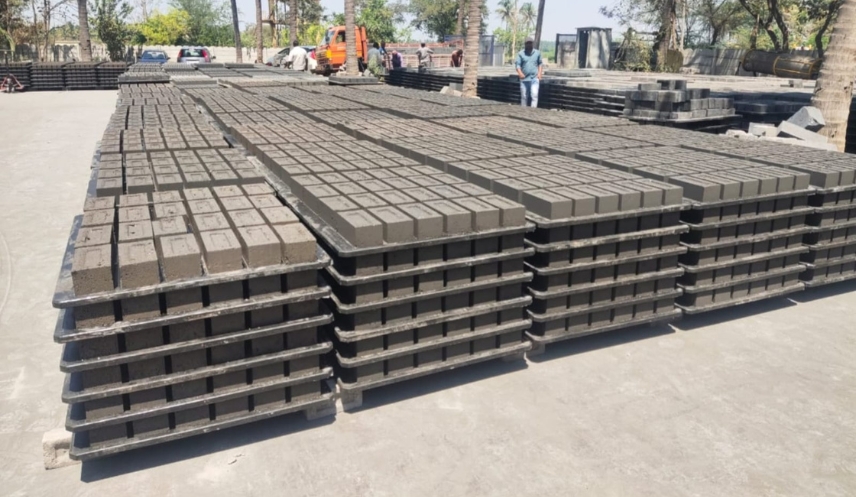

PWS Pallet Boards are crafted from top-quality densified hardwood fibers infused with BWP Grade Synthetic Waterproof resin. Each layer is meticulously treated with waterproof resin and subjected to intense pressure and superheated steam to ensure durability and longevity. The corners are precision-cut and the edges chamfered to prevent damage to machinery. Additionally, all saw cut sides are coated with enamel for added protection. The top and bottom surfaces of the pallet are constructed from multiple layers of Resin Coated Abrasion Resistant Synthetic Films, providing a shield against the corrosive effects of concrete.

Specification

- The board has a density of 1100 - 50 kg/m³, making it a durable and reliable option for various applications. It can withstand temperatures ranging from -10°C up to 120°C, ensuring its performance in a wide range of environments.

- With a maximum deflection of 3 mm when subjected to a weight of 500 kg over a 1 m² area at the recommended thickness, this board offers exceptional strength and stability. It is available in all sizes, with thicknesses ranging from 10mm to 70mm, providing versatility for different projects.

- Manufactured using a 3,800 tonne hydraulic press, this board boasts enhanced load-bearing capacity and high resistance to moisture absorption. Its transmission of vibration ensures high and homogeneous compactness of concrete, while its flat and jointless surface provides a smooth finish.

- Steel mesh reinforcements in the top and bottom surfaces of the board promote vibration homogeneity, further enhancing its performance. Additionally, the corners and sides are profiled to prevent damage to machinery, reducing cycle time and increasing production efficiency

- Overall, this board offers superior performance and a longer lifespan compared to softwood and hardwood pallets, making it a reliable choice for various industrial applications.